British Museum uses Printed Scaffold Sheeting to cover building work

Printed Scaffold sheeting has been used to cover the scaffold structure for the British Museum whilst renovation and construction work is being carried out.

The British Museum has a Greek Revival façade which has a total of 44, 14 meter high (45ft) columns. The pediment over the main entrance on Great Russell Street is decorated by sculptures depicting The Progress of Civilisation, which consists of 15 allegorical figures and was installed in 1852.

Project Print Management was commissioned to cover the main entrance pediment with a trompe l’oeil image to reduce the visual impact whilst building work was being carried out.

Printed Scaffold Sheeting is a good alternative to debris netting

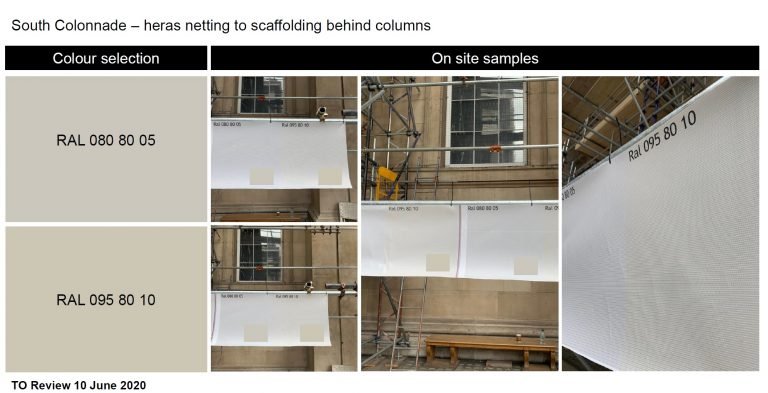

We were also asked to supply Printed Scaffold Sheeting which would hide the scaffolding behind the pillars. The sheeting was digitally printed onto a mesh PVC material which can be used as an alternative to monarflex or debris netting. By using our Printed Scaffold Sheeting this not only helps disguise the construction site and building work being carried out. It also protects the workers, machinery and open sites to wind, snow, and rain. The mesh sheeting will also help with dust and noise reduction.

As our scaffold sheeting is bespoke manufactured, we can make the panel size to better suit the scaffold. This makes the installation of the printed scaffold sheeting more efficient and gives a more professional finish.

The British Museum wanted to keep the sheeting simple, so we colour matched the Portland stone and printed a solid colour. The scaffolding on the roof area we printed to a sky effect. We can however print any design like stone, brick, or wood effect so it blends into the surrounding background.

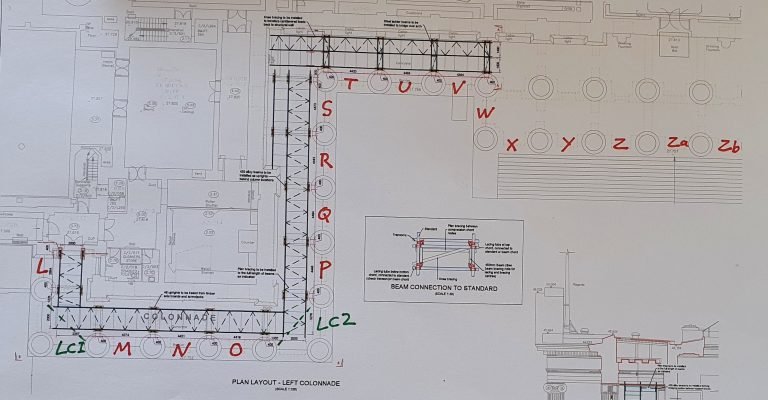

For this project recommended the scaffold sheets are dropped vertically down from the top of the scaffolding and hung. Unlike debris netting which is normally installed horizontally. This then allowed us to finish the sheets with a pocket at the bottom for a scaffold pole which then tensions the sheet. The top and sides of the sheets were reinforced with webbing and eyeletted every 300mm. The sheets sizes varied from 12 meter high x 4.9m wide to 3.3 meter x 0.5m. A total of nearly 50 panels totalling 2800 meter2 was produced making it one of the largest building wraps in the UK this year.

Unusual shapes too

Scaffolding is often not simple shapes and one of the many benefits of bespoke printed scaffold sheeting is we can manufacture the sheeting to complex shapes.

- Colour matching the Portland Stone

- Printed Scaffold schedule to make it easier for the installers

History of the British Museum

The British Museum was established in 1753 and is the most visit museum (which includes art galleries) in the United Kingdom with nearly 6 million visitors per year. The Museum has grown to become one of the largest museums in the world, covering an area of over 92,000M2. In addition, it has nearly 30,000 M2 of storage space and has a collection of over 13 million objects. However, the museum displays less than 1% (50,000 items) of its collection. The Queen Elizabeth II Great Court at the museum is the largest covered public square in Europe at 3692M2

- Mesh manufactured in Germany and fire retardant

The mesh PVC is manufactured in Germany by Verseidag, an innovative, well respected market leader in digitally printing materials. The mesh PVC is fire retardant to B-s3,d0 and M1 standards. This gives our clients peace of mind that our printed products are safe and fit for purpose.

- Printed in the UK for speed of service

Our digital printing is done in England on a super-wide Vutek UV inkjet 5 meter wide printer. Print resolution is around 600 dpi which is how we can deliver such realistic images. Lead times can vary but once the design / artwork has been signed off can be a matter of days if required.