BNP Paribas lift shaft printed protection screen

Transforming Lift Shafts into Art: Project Print Management’s Printed Protection Screen for BNP Paribas

When BNP Paribas, one of the world’s leading financial institutions, embarked on an ambitious lift refurbishment project at their Marylebone office in London, they faced a significant logistical and aesthetic challenge. The work was essential but came with the risk of visually disrupting a pristine and contemporary glass atrium in a busy corporate environment.

The solution? A bespoke printed protection screen—designed, produced, and installed by Project Print Management (PPM). This case study highlights not only the complexity of the task at hand but why PPM remains the preferred partner for large-scale architectural graphic solutions in high-profile environments.

The Challenge: Concealing Work in a Transparent Environment printed protection screen

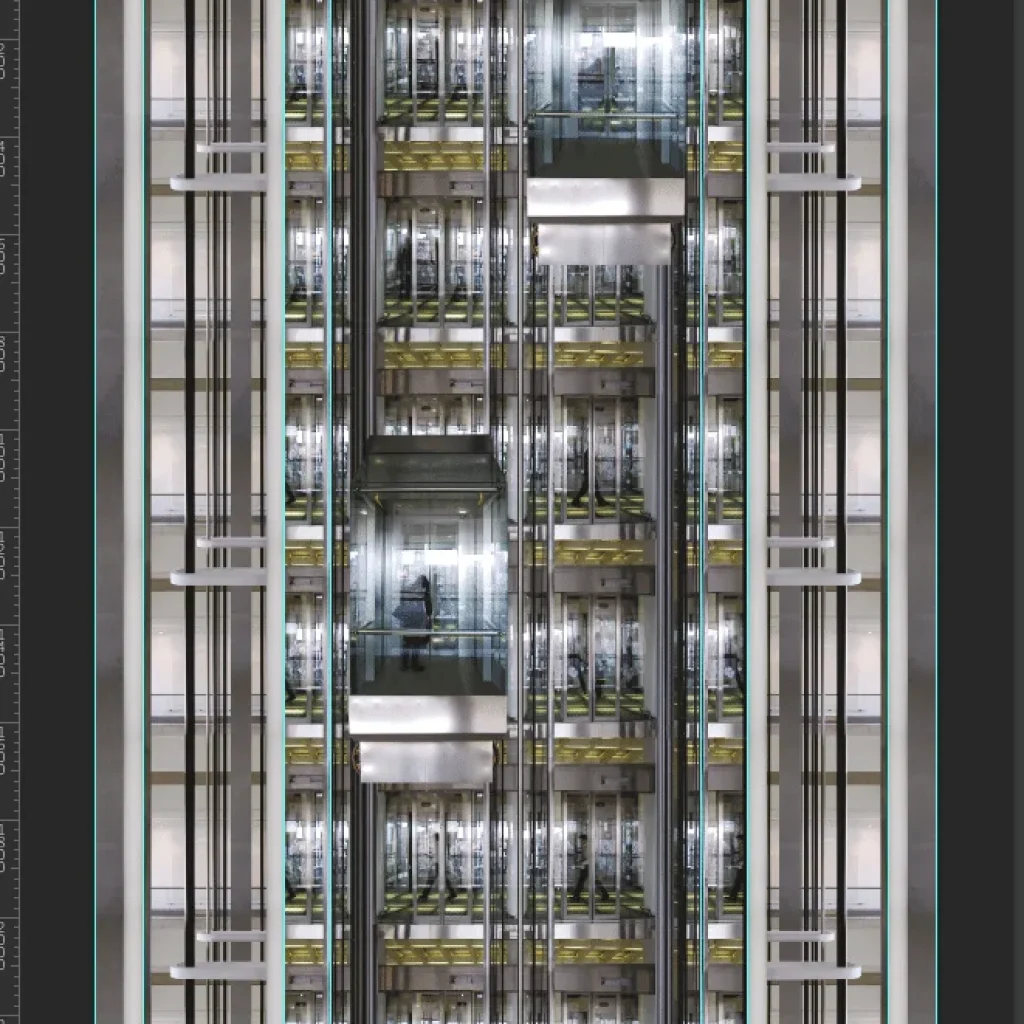

BNP Paribas was undertaking a comprehensive 10-month refurbishment of the five glass lifts located in two separate shafts within their central atrium. Two of these lifts were situated prominently at the front of the atrium, with the remaining three positioned more centrally. All five were constructed with transparent glass, offering unobstructed views of both the lifts and the lift shafts from nearly every vantage point in the building.

To maintain functionality during the extended refurbishment, one lift was to be worked on at a time, allowing the others to remain operational. However, this phased approach posed a new challenge: with the shafts being transparent, engineers and their tools would be visible to both staff and visitors. The client needed a solution that ensured public safety and maintained the professional appearance of the building—without scaffolding or excessive disruption.

The PPM Advantage

This is precisely the kind of complex, design-sensitive project that defines Project Print Management’s unique expertise. As specialists in printed architectural wraps and protection screens, PPM’s approach was significantly more cost-effective and logistically sound than traditional alternatives. Competing contractors had suggested the only viable solution would be full scaffold structures erected inside the lift shafts. This was both invasive and expensive.

PPM’s proposal not only eliminated the need for scaffolding but also came in £60,000 under the next closest bid. Just as crucially, PPM estimated the entire installation could be completed in just two weekends, compared to the six weekends proposed by competitors. This swift, smart, and cost-efficient methodology is what consistently sets PPM apart.

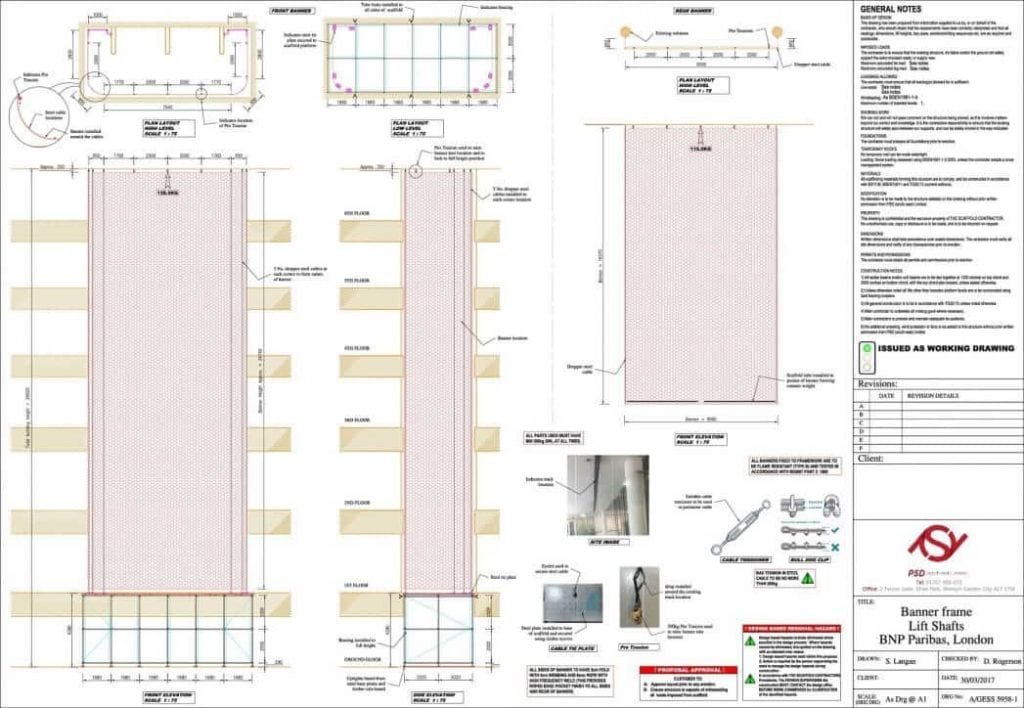

Engineering the Solution: Creating a Printed Protection Screen

At the core of PPM’s plan was an innovative installation technique that utilised the building’s existing service cradle—a motorised track system that circles the top of the lift shafts and is typically used for maintenance access. Cables were affixed to this cradle track and dropped vertically down the shafts. These acted as guides for the printed protection screen, which would be securely mounted to them.

The screen itself would be digitally printed on solid PVC—not mesh, as is more common in outdoor wraps—because indoor installations do not need to accommodate wind loads. The solid PVC provided both privacy and a physical barrier to protect against the unlikely event of falling tools or equipment. The chosen material was also fire-retardant, meeting stringent health and safety requirements for internal environments.

Installation: A High-Stakes Operation at 31 Metres printed protection screen

The actual installation was arguably the most demanding part of the project. The lift shaft in question rose to a height of 31 metres, requiring rope access engineers with specialised training in high-rise installations. Suspended from the top of the atrium, these professionals carefully winched the massive PVC banner into place, securing it with precision to the pre-installed cables.

The banner itself measured 25 metres high by 18 metres wide, making it a substantial engineering feat even in ideal conditions—let alone in the middle of a busy, high-profile corporate building. The entire operation was conducted over two carefully choreographed weekends to minimise disruption to BNP Paribas’ operations.

Results: Safety, Sophistication, and Seamless Integration

The completed printed protection screen met all of the client’s expectations. It concealed the ongoing lift refurbishment entirely, kept building occupants safe from any potential hazards, and blended seamlessly with the visual identity of the atrium.

Most importantly, the project demonstrated how creative problem-solving, technical know-how, and aesthetic sensitivity can come together to deliver world-class results—even under highly restrictive conditions. The client was not only impressed by the end product but also grateful for the cost savings, the quick turnaround, and the professional collaboration offered by the PPM team throughout the process.

Design Integrity: Where Aesthetics Meet Accuracy

While the physical protection and installation methods were essential, the visual design of the printed screen was of equal importance to BNP Paribas. The screen needed to seamlessly integrate into the visual language of the space, preserving the premium look and feel of the corporate environment.

This is where PPM’s 25 years of experience in large-format printing and trompe l’oeil artistry came into play. Trompe l’oeil—French for “deceive the eye”—is a design technique that uses perspective and shading to create a realistic three-dimensional appearance. If the visual elements on the screen were out of scale or improperly aligned, the illusion would collapse, undermining the entire project.

To ensure perfection, PPM worked alongside the BNP Paribas in-house design team. First, the riggers installed the cable guides and conducted a precise survey of all mounting points. From this, PPM created an accurate vector template—essentially a digital blueprint—onto which the final artwork could be dropped. The result? A truly impressive piece of visual design that looked as though it belonged as a permanent feature of the space.

Cutting-Edge Print and Finishing Technology

Manufacturing the printed protection screen demanded a combination of high-spec materials and precision engineering. The screen was produced using EFI’s Vutek GS500r, one of the most advanced superwide digital printers in the world. Capable of printing at widths of up to five metres and in ultra-high resolution, the Vutek GS500r delivers vibrant, detailed prints with exceptional durability.

Once printed, the screen underwent a meticulous finishing process. Hems and eyelets were added using the Forsstrom TDW 200-1000, a high-frequency welding machine known for its strength and consistency. These components were essential to ensure that the screen could be tensioned perfectly, hung safely, and withstand the demands of a months-long installation inside an active commercial space.

About BNP Paribas

BNP Paribas has had a presence in the United Kingdom for nearly 150 years and continues to be a key player in the European financial sector. The UK serves as a strategic hub for the Group, which operates across two primary divisions:

- Corporate & Institutional Banking (CIB): Serving corporate clients and financial institutions with financing, advisory, and global market solutions.

- Retail Banking and Services: Offering a wide range of personal and business banking services across multiple sectors.

With a strong focus on innovation, responsibility, and sustainable growth, BNP Paribas consistently seeks partners who can match its high standards and forward-thinking approach—making their collaboration with Project Print Management an ideal fit.

Why Project Print Management?

This project encapsulates why Project Print Management continues to lead the way in specialist printed screening solutions. From high-end corporate environments and historical landmarks to retail spaces and hospitality venues, PPM provides:

- Creative vision: with technical precision.

- Efficient, cost-saving alternatives: to traditional methods.

- End-to-end project management:from design consultation to final installation.

- Unmatched expertise: in printed architectural wraps and trompe l’oeil graphics.

In environments where both safety and aesthetics are non-negotiable, PPM proves time and again that it’s possible to achieve both—without compromise.

If you’re planning a construction, refurbishment, or installation project where appearances matter just as much as performance, contact Project Print Management today.