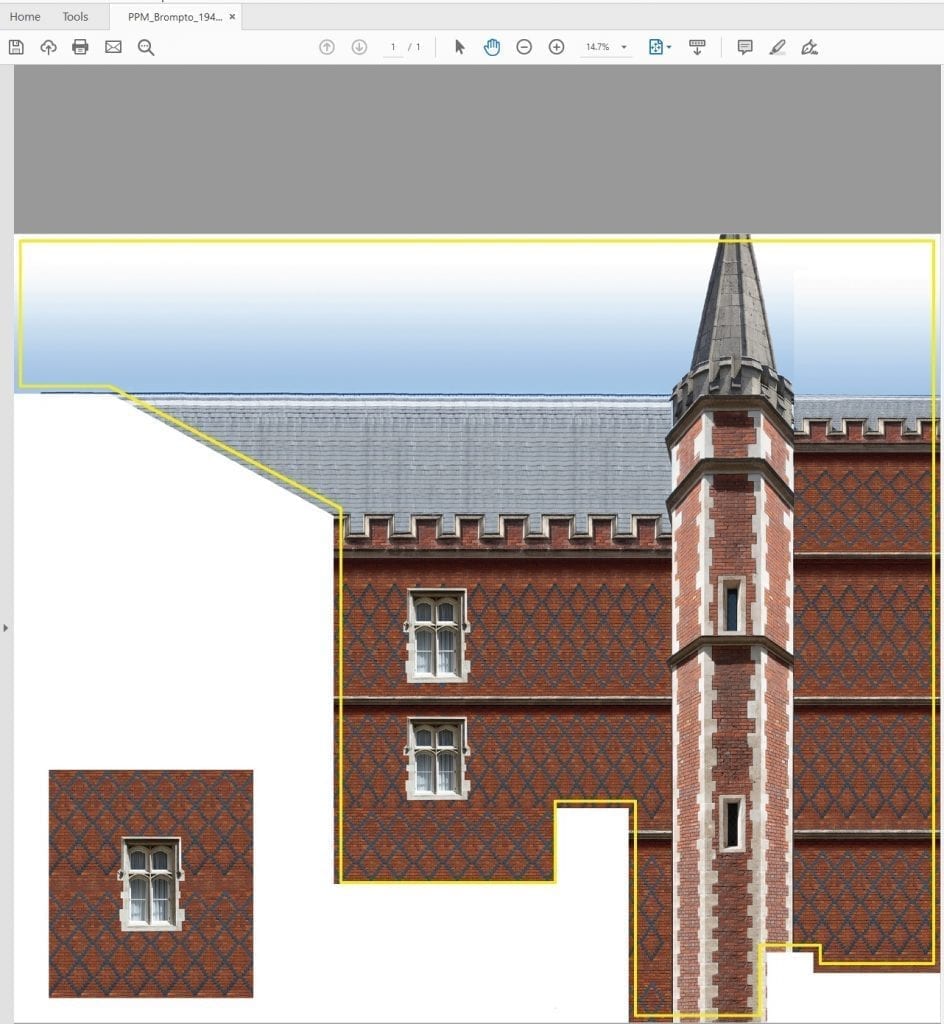

This facade scaffold wrap is an excellent example of how quality and well executed building wraps should look like. Our brief was to hide or disguise the scaffolding which housed a hoist while renovation work was being carried out. The scaffolding and hoist will be up for 18 months and would be an eyesore for tenants living at this prestigious development. This scaffold wrap was a complex piece of work and a good sample of what we can wrap on such a large scale.

Its all about teamwork

At the heart of delivering a quality facade scaffold wrap is the sub-frame. Getting this right is a huge part of ensure the building wrap looks right.

This project the client wanted to use there own scaffolding contractor to supply the sub-frame. We suggested they utilise our experienced supervisor on a day rate to train and assist their staff with the installation of the sub-frame. Once completed the supervisor surveyed the frame so our artwork team could produce a template for the design.

Getting the artwork prepared for facade scaffold wrap

As one would expect getting the design correct is key to getting the facade scaffold wrap looking right. But one must not get to bogged down in the architectural detail unless it’s for an exhibition or conservation work. The ultimate goal is to make the building wrap look like its not even there.

Photographing the building can be very tricky especially high thin buildings. The higher the building the perspective becomes more of an issue. The perspective then needs to be corrected as part of the artwork process.

Ensuring scale, colour and perspective are accurate true to life. The design needs to fit into its environment complimenting the surrounding buildings so becoming part of the town or landscape.

The digital printing processes facade scaffold wrap

Digitally printed on a five-meter super wide format printer onto a mesh PVC. Finished with Large eyelets (internal hole size 14mm) at 300mm centres through a 6mm roped edge pocket with 5cm fold with 5cm webbing to inside of fold with a 5cm high frequency weld around perimeter of all sides. Rear ties running vertically at 5m centres welded with a 5cm weld and webbing to the rear of the banner, 5cm webbing with large eyelets (14mm internal hole size) at 500mm centres. Rear ties to be tucked inside top/bottom (perimeter) weld to prevent peeling.

History of the Bromptons

The Bromptons was originally a hospital built in 1844 on a three-acre area which was formerly a market garden.

The foundation stone for the new hospital was placed by Prince Albert in June 1844. Queen Victory was a sponsor for the hospital and visited the Bromptons numerous times. Her signature is in the visitor’s book and now on display in the building.

Redeveloped sympathetically by Northacre PLC in 1997. They wanted to preserve its architectural characteristics of the hospital retaining a number of original features and is now regarded as one of the finest residential developments in London.

For more information on facade scaffold wrap please click here, or for our latest print projects please visit our blog.